Degassing Inserts

Scope of application

The high-quality FLUXX® Degassing Inserts make it possible for gaseous substances to diffuse, thereby preventing pressure from building up and decreasing in the containers – including bottles, canisters, drums and IBCs. The membranes are hydrophobic as well as oleophobic, and as a result, they are not saturated even by liquids with a low surface tension.

Your contact person

Kevin Eckert

Head of FLUXX

Packaging & Industrial

NEW: FLUXX® Degassing Inserts F38 HF & EHF

You need a venting solution with ultra-high airflow?

The search is over – We have the appropriate products for you!

Our two new FLUXX® products – the F38 HF (High-Flow) and F38 EHF (Extreme High-Flow) – are guaranteed to impress with ultra-high airflow performance.

These product solutions enable the optimal venting of various containers in heavy pressure situations with highly outgassing substances.

Both products are available as press-in and snap-fit (LOCK) versions with long neck as well as shortened neck (SN). They also comply to food industry standards.

Additional information

Application examples

- Liquid food

- Hazardous substances and other chemicals

- Agrochemicals

- Cleaners

- Hygiene and care products

Benefits (X-tra)

- Continuous pressure compensation

- Prevent containers from swelling and collapsing

- Reliable protection against leaks

- Drip-off edge for a rapid re-ventilation after contact with liquids

- Easy to install

- Declaration of food conformity

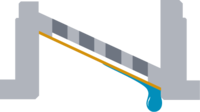

Patented drip-off edge

Thanks to the diagonally developed membrane surface of the innovative FLUXX® Degassing Inserts, liquids can rinse off immediately after contact and thus the membrane remains fully breathable at all times.

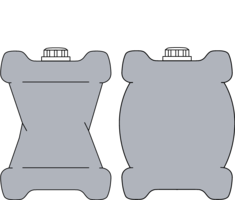

Broad product portfolio

For a continuous pressure compensation of containers, our FLUXX® Degassing Inserts F15, F17 & F38 – without and with catch (LOCK) – can be pressed in customized closures or other applications. The Degassing Inserts contain various high-performance membranes which were validated for specific product solutions.

Mode of operation

With FLUXX®

Degassing System

Without

degassing system

Materials

| Plastic insert: | Polyethylene (PE) |

|---|---|

| Membrane: Backing: | Polytetrafluorethylene (PTFE) Polypropylene (PP) |

Additional materials upon request.

Suitability for hazardous goods

Because of the construction and performance values, our FLUXX® Degassing Inserts can meet all requirements for authorization with various containers – especially in accordance with the test specifications set forth in the ADR regulations.

Declaration of food conformity

Our listed products comply with regulations EU no. 10/2011, EC no. 1935/2004, LFGB, FDA, Mercosur as well as JFSA (Japan) and are fit for human consumption under the food law as well as from a physiological point of view – inspected and approved by certified testing institutes.

Installation variants

Without catch

With catch (LOCK)

Please consider our installation instructions.

Chemical resistance

Our products achieve a high chemical resistance to many liquids. However, we cannot guarantee comprehensive chemical resistance of specific applications. Therefore, we recommend individual testing of customer applications prior to use – with the support of our experts.